Agglomeration and granulation – in top form at Glatt

Why this is important: Agglomeration and granulation are highly efficient processes for combining smaller particles into larger units.

The respective goal: to change the shape of powdered particles in such a way that their properties are improved. The added value for you: Product handling is facilitated and productivity increased.

What does agglomeration and granulation mean at Glatt – and which process is the perfect fit for your material? When selecting the ideal process, we do not only take the desired product properties but also production-specific aspects such as process times or resource utilization into account. We define all the relevant target parameters precisely in advance.

Agglomeration and granulation: Our high-end solutions for shaping particles

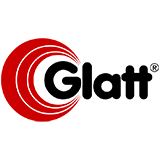

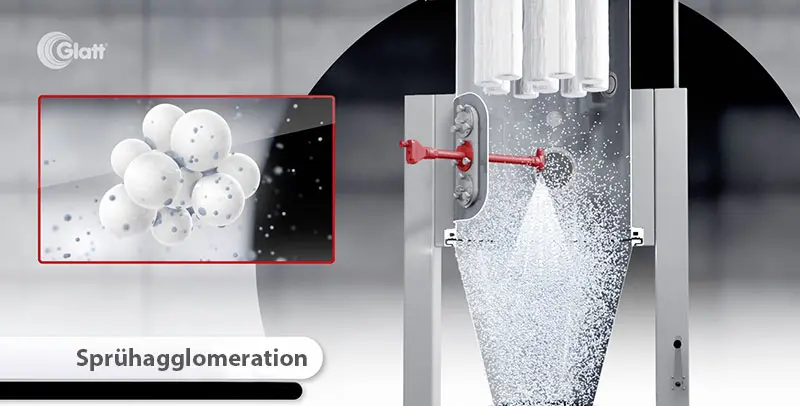

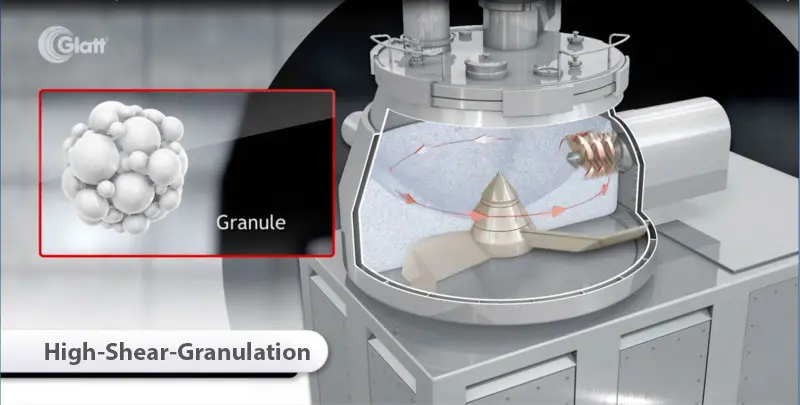

A good example of agglomeration is fluidized bed spray agglomeration: Among other things, it ensures that powders dissolve particularly easily. Examples of granulation are spray granulation and high-shear granulation. In microencapsulation, even liquids can be encapsulated and embedded in granules.