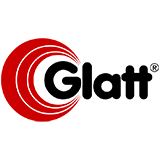

High shear granulation – for particularly compact granules

High shear granulation, also known as vertical granulation or wet granulation, is a highly developed shaping process for granulation.

We have continuously optimized this process, which has been in use for a long time, for applications in the pharmaceutical industry. In vertical granulation, various powdery ingredients are formed into larger uniformly distributed, very compact granules.

How we carry out high shear granulation

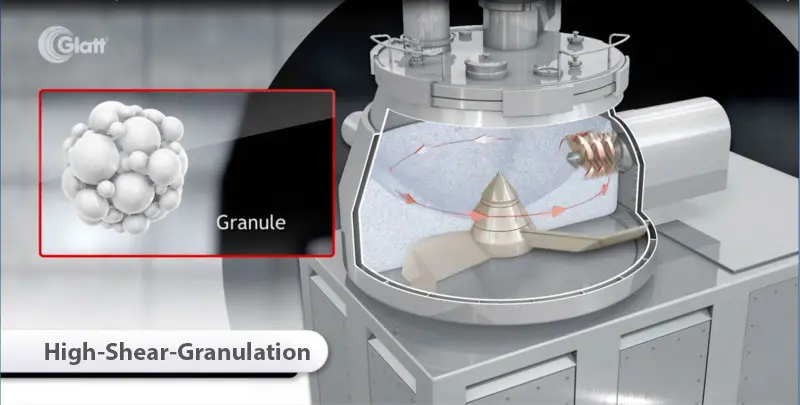

The shaping process for granulation takes place in a closed vessel equipped with mixing tools and a chopper. The particles are simultaneously pulverized and mixed while a binder liquid is added. This creates liquid and solid bridges and very dense granules are formed.

Originally, the granulating liquid was poured into the product. Today, we achieve a better-metered distribution via a spray nozzle – a more uniform granulate is produced.

What high-shear granulation does particularly well

Wet granulation makes it possible to produce particularly compact granules – the high mechanical shear effect of the mixing tools rotating at the bottom or top makes this possible. The produced granules are denser than if they were achieved through the fluid bed process. It does not matter whether the shaping process for granulation operates in batch or continuous mode.

Your advantages with vertical granulation

The granules that we produce with high-shear granulation can be optimally processed. Their characteristics are advantageous for many applications in the pharmaceutical and related industries, among others:

- particularly compact structure

- high bulk density

- very flowable and easy to compress