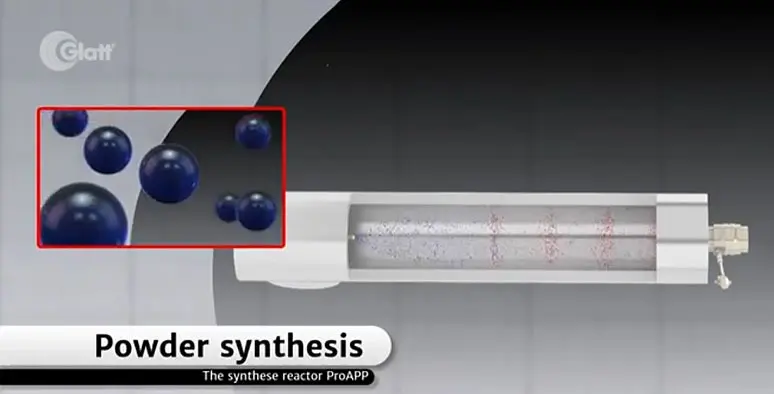

Targeted design of new types of powders with precisely adjusted properties

Glatt powder synthesis in pulsating gas flow is a technology for the production, modification or coating of powder particles in the nanometer and micrometer range.

Our technology is applicable to all industries where innovative particle systems for specialized high-performance materials are required. Possible applications for our proprietary powder technology include catalytic materials, ceramic materials, pigments or battery materials.

The processes of spray pyrolysis, spray drying, and spray calcination take place in a continuously operated vertical reaction tube. Depending on the choice of process parameters, materials are produced, optimized, and functionalized in one of these ways. For this purpose, they are not in a laminar flow, but in a pulsating gas flow, and are thus in a state of turbulent flow. This leads to thermodynamic changes in the reaction space. It is precisely this that enables the properties of the generated powders to be specifically influenced.

The processes of spray pyrolysis, spray drying, and spray calcination take place in a continuously operated vertical reaction tube. Depending on the choice of process parameters, materials are produced, optimized and functionalized in one of these ways. For this purpose, they are not in a laminar flow, but in a pulsating gas flow, and thus in a turbulent flow. This leads to thermodynamic changes in the reaction space. And it is precisely this that enables specific influence on the properties of the generated powders.

Highest homogeneity and no hard aggregates

The highly turbulent tube flow leads to a strong mixing process of the gas and the droplets or particles within it. Temperature gradients in the gas and velocity gradients in the flow are homogenized. The absence of thermal hotspots prevents hard aggregates and all particles experience the same time/temperature regime. The generated particles can be easily separated and dispersed afterwards.

Extremely high rates of transfer for both heat and mass

Pulsation maintains a relative velocity between particles and gas stream along the entire length of the reactor. Boundary layers around the particles are nto able to form. Heat and mass transfer are thus significantly accelerated.

Glatt powder synthesis with all processes in a single step

Glatt powder synthesis combines particle formation, drying, and calcination and in a single step. If required, coating can be integrated to produce functional core-shell particles with specific layer thickness, porosity, and activity properties.