Microencapsulation: protects sensitive substances

Encapsulation in the fluid bed or spouted bed – for powders and even liquids

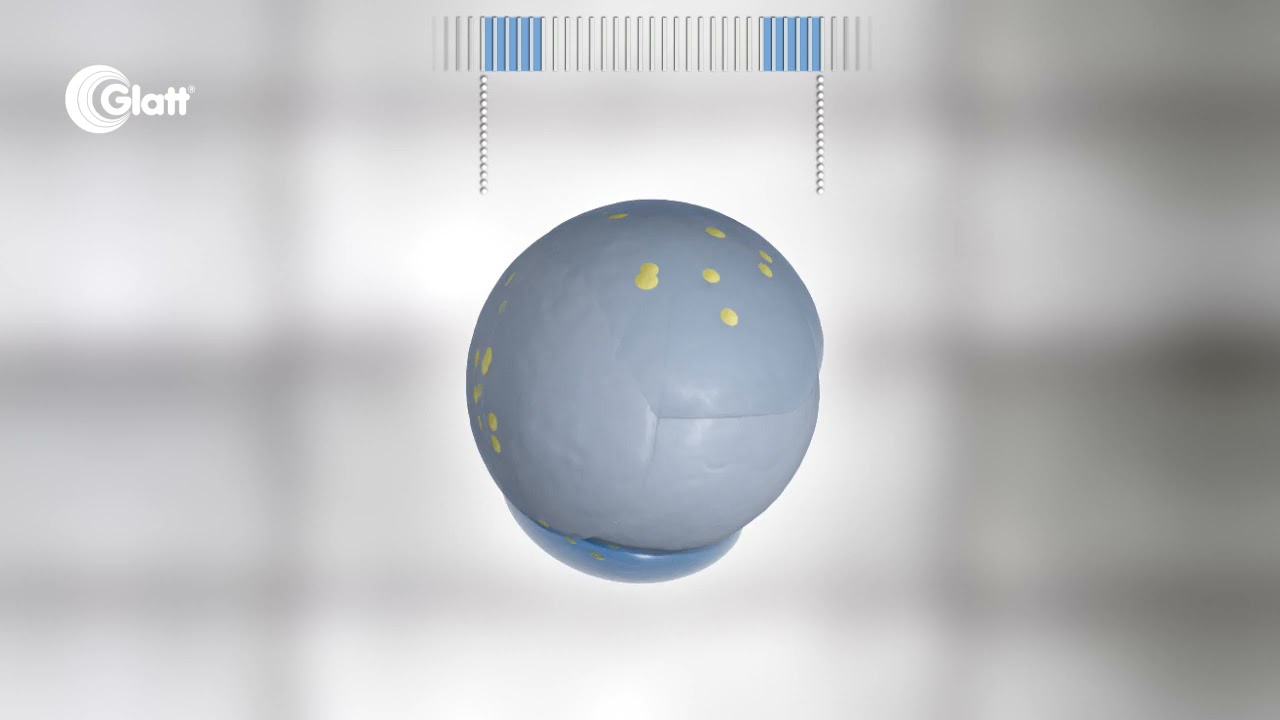

Microencapsulation is a special variant of spray granulation that is ideal for protecting sensitive substances. The process is ideal for forming compact particles that have a smaller surface area and thus offer little surface area for oxygen to attack.

Microencapsulation of oils and other hydrophobic substances proceeds in two stages: The actual encapsulation is the formation of an emulsion with a suitable emulsifier, which forms the protective film. The size of the droplets should be very small so that they have sufficient stability in the subsequent drying step. In the second step, the liquids are encapsulated and embedded in compact granules. Especially as a manufacturer in the food and pharmaceutical industry you will benefit from this process.

Are you planning a project in the field of microencapsulation?

Take advantage of our extensive experience in handling oxidation-sensitive substances and test the possibilities in our technology center. We will be pleased to tell you:

Which process would be ideal for your product – encapsulation in the fluidized bed or spouted bed or layering.

Which product properties granules from microencapsulation can have.

How we can support you, for example, from the formulation of the liquid to production on an industrial scale – also on site in our Technology Center in Weimar.