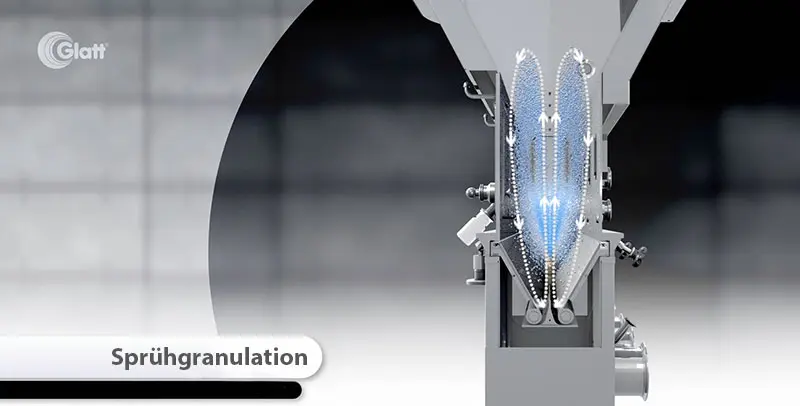

Spray granulation in the fluid bed and spouted bed: from liquids to flowable granules

Spray granulation briefly defined: Liquids are dried and flowable granules are built up. Learn how the process works and how you can benefit from it.

We spray liquid starting materials, such as solutions, suspensions or melts, into the fluid bed or spouted bed system and dry them. Compared to agglomerates, spray granules are denser and harder.

This process is often referred to as granulation drying or build-up granulation. The small and irregularly shaped spray granules score high due to their rapid sinking properties with improved solubility.

Fluid bed or spouted bed spray granulation is a versatile continuous process. Production volumes can reach up to several thousand tons per hour. The process is therefore ideal for applications in all powder processing industries – from chemicals to pharmaceuticals.

This is how our process for obtaining flowable granules from liquids works:

We spray liquid starting materials such as solutions, suspensions or melts into the fluid bed system and solidify them by drying or solidification.

Due to the high heat exchange, the aqueous or organic solvents evaporate or vaporize immediately, and the solids form small particles as carrier cores. These are wetted with further liquid, which in turn form a solid shell around the carrier core after drying. This process is repeated continuously in the fluidized bed. The granules grow homogeneously in layers to the desired size.

Due to the so-called air classification in the discharge, finished particles are continuously carried out in the air stream, while the drying process for the remaining particles continues.

The result is spray granules that grow onion-like, layer by layer, to the desired size; we produce particle sizes from 50 micrometers to 5 millimeters. Spray granules are not only free-flowing, but also very dense and resistant to abrasion due to their growth in layers.

Fluid bed or spouted bed spray granulation is advantageous for these applications:

Industrial applications that need to convert liquid substances into a dry, stable product form will benefit from this process. We can precisely define the properties required in each case when obtaining flowable granules from liquids:

- for further processing as solids in food, animal feed or detergents

- to reduce the product volume for transport and storage

- to increase the stability of chemical substances

- or for the treatment of thermally sensitive products such as enzymes, proteins or microorganisms.

Use the advantages of spray granulation for your requirements:

What properties are important for your project? We can specifically influence parameters such as particle size, residual moisture, and solids content in fluid bed spray granulation and achieve a wide variety of product properties.

Our dust-free spray granules have a dense surface structure and high bulk density. Due to their small surface area, they are not very hygroscopic, so they hardly attract ambient moisture. In addition, they are:

- flowable

- abrasion-resistant

- free-flowing

- easily soluble

- optimal dosable